The Victoria Hand Project was launched eight years ago in Canada by engineers. Its main goal is to help provide arm prosthetics for those who have lost upper limbs. To solve this issue a 3-D prosthetic technology has been developed as well as a system for search of partners in different countries. Engineers share their technology, providing necessary materials, while doctors work with patients and produce prosthetics for them. It is important to understand that each specific case requires a concrete type of a prosthetic and it is doctors who decide if this particular type will fit the patient). The project’s CEO, Michael Peirone, told us about how everything works.

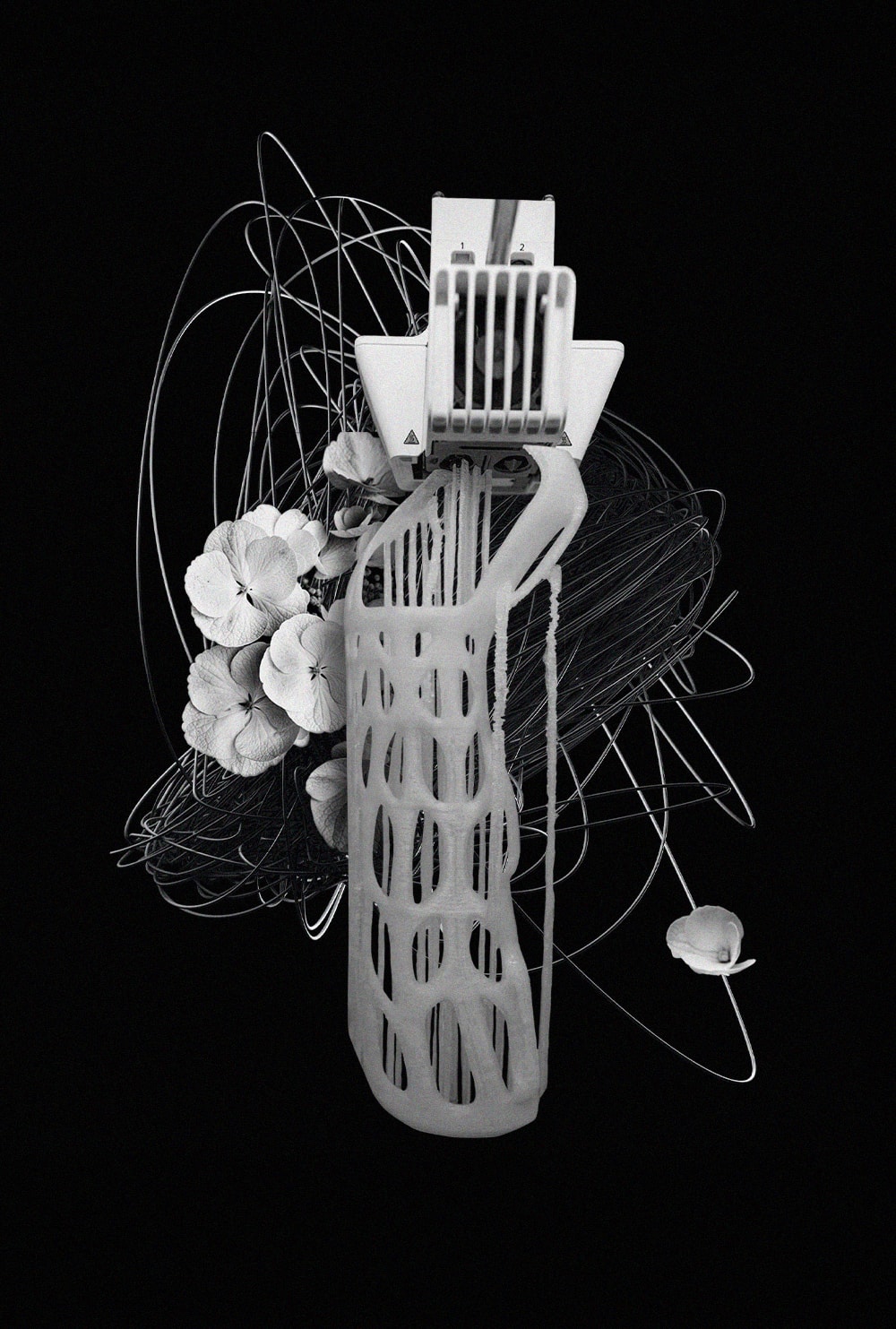

Today with the help of 3-D printing a team of experts from the University of Victoria produce arm prosthetics, while also training high-qualified would-be specialists in 14 countries and providing them with equipment.

The project is being funded by private donations as well as by commercial organizations and foundations across the globe.

It takes a few days to create a 3-D arm prosthetic. One such device costs about 100-150 USD in materials.

So far, the Victoria Hand Project has already helped over 250 people in different countries, including Kenya, Egypt, Uganda, Nepal, Haiti, Cambodia, Ecuador, Canada, USA and others.

At the beginning of 2023 the project extended its activities to Ukraine. A representative of the initiative visited two partner clinics in Lviv and Vinnytsia in order to conduct initial training of local experts, set up equipment and demonstrate its operations.

The funds received from benefactors are fully sufficient to provide high-quality prosthetics for 100 Ukrainians who have lost their limbs in the war. The team of the project are convinced that they can respond to a large number of requests after the full-fledged launch of their activities in Ukraine.

It all began as a university project‘

The idea to help people who lost their limbs was hit upon by Dr. Nick Dechev, a professor of Mechanical Engineering at the University of Victoria. Nowadays he is the Founder and the Chief Technical Officer of the company.

Michael joined the initiative in 2014 while studying biomedical engineering at the same university. For the then student, it all began with his curiosity. Eventually, he came to realize that this technology could change the world. Working on the Victoria Hand Project and volunteering, Michael gained a lot of experience and knowledge. Since 2017 this has been his main field of activity.

The Victoria Hand Project began as university research work. It was launched to check just how feasible it was to produce arm prosthetics with the help of 3-D printing technology. Dr. Dechev’s team did a trial of this technology in Guatemala. Afterward, the participants of the project asked the initiative to let them continue using the equipment in the future. That was how the idea of launching an organization that would provide such prosthetics for people all over the world had appeared. Since then, it has begun growing, working in different countries’, says Michael.

Currently, the team is developing a technology for prosthetics, also searching for partner clinics and training personnel on how to use this technology and produce arm prosthetics directly on-site. The Victoria Hand Project provides partners with 3-D printers, 3-D scanners, different tools as well as parts of arm prosthetics.

Apart from Michael, there are three other members working full-time in the project. Also, the team is regularly joined by volunteering students. There were 50 of them last year.

‚We still work at the University of Victoria. It offers us access to the communication with students interested in acquiring new skills and helping people. Some of them think that 3-D printing is cool and that is why they are eager to learn this technology. At the same time, others may see a bigger picture: a hand that they make can change someone else’s life. For some this work turns into passion, just like it did for me. When you see the faces of these people who are smiling… This is incredible’, Michael says.

“Main advantage – cheap technology”.

According to Michael, the price of one arm prosthetic varies from 100 to 150 USD. This is the main advantage of 3-D technology.

‚It is also important that the production takes place in the countries where we work. Our plan is to provide clinics with 3-D printers. In doing so, we enable them to make arm prosthetics on site, which accelerates the process by a lot. People can receive prosthetics immediately, without having to order them from abroad or waiting for the delivery’, Michael says.

Also, thanks to the 3-D printer the end product can be adjusted.

‚You can make sure that the prosthetic fits in with the body nicely, which makes the process much easier. The expert inserts parameters in the printer and goes about their business while the machine is doing everything on its own‘, says the CEO of the project.

To produce an arm prosthetic a sketch needs to be drawn first. Then with the help of 3-D printing separate parts are produced that are then have to be assembled.

‚This may take up to 2 or 4 days depending on the experts’ experience in the parameters of 3-D printing. To have a part of the prosthetic made, which is then put on the limb of the hand, the patient has to come to the clinic. They are then examined, with experts preparing a plaster cast that would correspond to the size of the hand. Subsequently, the cast is scanned. A model is then designed on the computer that will be used to print the 3D prosthetic. It normally takes 6-8 hours for the part of the prosthetic that will be put on the limb of the hand to be printed, depending on the size’, says Michael.

Parts of the limb may not fit some people, which will require certain modifications.

‚The project‘s team consists of engineers. We work with professionals in the field, letting them decide whether such a device would fit a particular person. This is of extreme importance. Although we have obtained experience in prosthetics, we still rely on clinics that have done specific training. Arm prosthetics can be created only in cooperation’.

‚The project is aimed at supporting the local healthcare system‘

At present, Michael and his colleagues work in 14 countries. Recently they began helping in Canada and the USA. Partnerships always begin with personal connections – through friends, acquaintances or colleagues. They help find relevant clinics, raise necessary funds and support the project in the future.

‚For example, in Nepal we have two students who at that time were studying at the university. Their father is a surgeon who set up a clinic in this country. We began cooperating with him in 2016. After the boys graduated from the University, they continued to help us’, says Michael.

He also says that his team receives lots of letters from different countries offering to cooperate.

‚Normally we say that we would love to help but that we have a small team and are forced to search for funds. Luckily, the growth of the project lets us constantly help a larger number of people‘.

The team has provided arm prosthetics for over 250 people so far, while trying to increase the number every year. The result also depends on the capacity of their partners.

‚In Kenya, for example, partners can help more since they have a big team that has already mastered the technology. There are other partners with whom the process takes longer. Certain delays have also occurred due to the pandemic. At present, thanks to the expanded activities in the USA we have the opportunity to help more’, says Michael.

‚Our project is about supporting the local healthcare system. There is this expectation shared by many, according to which people will work for free. However, our model is different, since we pay doctors and technicians for their time, which makes it more resilient in the long term. Those who are engaged in the project also work in hospitals, helping us a few times a week’, says Michael.

How will the project Hands for Ukraine be implemented?

Recently the team began working with partners in Ukraine.

‚We have started receiving messages from people who have found us through a search engine. Here in Canada we’ve got a lot of acquaintances who assist us in establishing contacts throughout the world. That was how we contacted clinics in Lviv and Vinnytsia, with which we are going to cooperate within the framework of Hands for Ukraine‘, says Michael.

According to him, the team cannot go to the military zones unlike ‚Doctors without Borders‘ or the ‚Red Cross‘. However, they are able to pass on knowledge and technologies to Ukrainian clinics that will be dealing with arm prosthetics. For example, one of Michael’s colleagues, Nick Dechev, visited Ukraine in January 2023 so as to launch the process.

‚We brought 3-D printers and scanners for two clinics in Lviv and Vinnytsia. In June our team is planning to visit both of them to cooperate with professionals on site and to tell them how it all works‘, says Michael.

After the training the Canadian team are intent on continuing to offer technical assistance to their Ukrainian partners, as well as materials and equipment, including plastic and metal parts so that Ukrainian clinics would be able to produce prosthetics by themselves. This is exactly how the Victoria Hand Project has been cooperating with the partners from Nepal since 2016.

‚They use our equipment which continues to be operational. Such a model is gaining popularity across the globe. This is a long-term local partnership‘, believes Michael.

The CEO also says that doctors at both Ukrainian clinics will be communicating with potential patients identifying which of them will require a certain type of prosthetics.

‚There is one private hospital that already has experience working with 3-D printing and the other one is a state hospital. By working with different types of clinics we are capable of ensuring access to our initiatives for a larger number of people who can see how it all works in both cases’.

The Victoria Hand Project is a charitable foundation which exists thanks to the support from benefactors in Canada and the USA.

‚We need money to cover expenses on equipment and spare parts, as well as on salaries. We help people who often cannot afford prosthetics. Donations will cover the costs of devices and most of the expenses incurred by the clinic’, says Michael.

In future the Victoria Hand Project is planning to expand and strengthen partnerships with clinics the world over.

‚In 3-D printing we see the opportunity to also produce other devices. Given that we are engineers, we are constantly looking for new ways of using technologies as well as developing our own software. Our team is trying, as much as we can, to facilitate the process of producing prosthetics for people in the world. We see the kind of the potential that we can fulfill in the project and the needs we can cover. And we do just that’, Michael says.